Personalized Injection Molding: Crafting Approaches for Special Requirements

In a environment where conventional approaches often fall short, bespoke molding processes emerges as a crucial method for producing tailored products that fulfill particular requirements. This innovative technique allows producers to produce plastic parts with accuracy and unmatched adaptability. Through shaping substances into desired forms, companies can cater to unique needs across various sectors, from vehicles to domestic products.

Tailored injection molding not only enhances product performance but also provides chances for creative creativity and efficiency. By leveraging advanced technologies and high-quality substances, producers can achieve intricate geometries and exceptional quality. As companies seek to distinguish themselves in a challenging landscape, bespoke injection molding stands out as a strategic option for developing distinctive items that resonate with their target audience.

Understanding Tailored Injection Molding

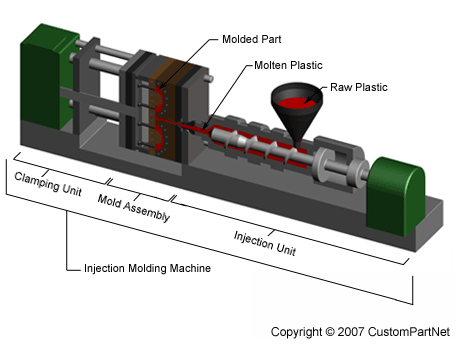

Custom injection molding is a production process specifically designed to produce parts and components with precision and efficiency. This technique involves injecting molten material, often thermoplastics or heat-curing polymers, into a custom-made mold. Once the material cools and solidifies, it takes on the shape of the mold, enabling for the mass production of uniform parts. This method is especially beneficial for businesses looking to produce intricate geometries that would be difficult or impossible to achieve with alternative fabrication methods.

One of the primary benefits of custom injection molding is its ability to customize products to specific requirements. Companies can work closely with manufacturers to design molds that meet their unique needs, whether in terms of size, form, or performance. This level of personalization opens up opportunities in multiple industries, including automotive, medical, and consumer goods. Moreover, the ability to produce large volumes at a low cost per unit makes custom injection molding an appealing option for both minor and large-scale production.

In addition to its versatility, custom injection molding also offers significant benefits in terms of material selection and quality control. With a wide range of materials available, businesses can choose the most suitable options based on application requirements, such as durability, bendability, or resilience to chemicals. The process also allows for strict tolerances and surface finishes, ensuring that the final product meets the top standards. As a result, custom injection molding stands out as an essential method for businesses seeking tailored manufacturing solutions.

Benefits of Tailored Solutions

Tailored injection molding offers major advantages for companies seeking distinctive manufacturing solutions. One of the primary benefits is the capacity to produce intricate shapes and designs that standard molds cannot handle. This versatility enables companies to create parts that perfectly fit their specifications, enhancing functionality in their products. By using tailored molds, manufacturers can also optimize material usage, reducing waste and cutting production costs overall speaking.

Another important benefit of custom injection molding is the opportunity for material selection. Different applications often require distinct materials that can deliver desired characteristics such as durability, flexibility, or resistance to substances. Tailored solutions allow businesses to choose from a wide range of materials, ensuring that the final product meets specific industry standards and end-user expectations. This level of customization ensures resilience and performance, considerably adding to the product's worth.

Additionally, custom injection molding can lead to faster lead times for production. With the specific molds designed for particular needs, manufacturers can optimize their processes and reduce the time from production to market. This adaptability is notably advantageous in rapid industries where time-to-market can make a critical difference. The ability to quickly adapt to changing market demands with tailored solutions can position companies as pioneers in their respective industries.

Uses In Sectors

Tailored injection mold manufacturing is used in various fields, demonstrating its adaptability and versatility. In the auto sector, it plays a crucial role in producing components including dashboards, electronic casings, and safety covers. By facilitating intricate shapes and light parts, custom injection molding enhances better functionality and safety in vehicles. The ability to manufacture parts that satisfy specific mechanical and aesthetic requirements is a key benefit in this intensely competitive industry.

Within the retail market, tailored injection molding assists manufacturers produce unique, attention-grabbing products that differentiate themselves in the shelves. From packaging to unique tools, this process enables the production of items that meet specific consumer demands and industry trends. Businesses can attain detailed details, colors, and textures, ultimately improving the user experience and fostering brand loyalty through unique designs.

The medical sector also heavily utilizes custom injection mold manufacturing for making detailed devices and parts. Medical applications demand precision and compliance with strict regulatory standards, which makes custom solutions crucial. Items such as medical syringes, surgical tools, and housings for electronic monitoring devices are just a sample of how custom injection molding can satisfy the needs of the healthcare sector, providing reliability and safety in high-stakes environments.